Monte Carlo Simulation

Please attach your source code.

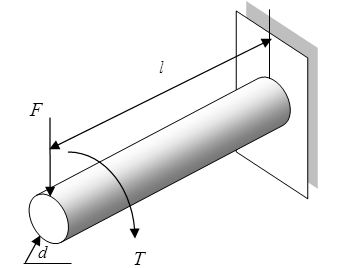

1. The limit-state function of a shaft in a speed reducer is defined by the difference between the strength and the maximum equivalent stress. It is given by

![]()

where

![]() mm, the diameter of

the shaft

mm, the diameter of

the shaft

![]() mm, the length of the

shaft

mm, the length of the

shaft

![]() the external force

the external force

![]() the external torque

the external torque

![]() the yield strength

the yield strength

The distributions of the independent random variables are given below.

Table 1 Distributions

|

Variables |

Mean |

Std |

Distribution |

|

External force |

2000 N |

220 N |

Normal |

|

Torque |

450 N·m |

50 N·m |

Normal |

|

Strength |

250 MPa |

30 MPa |

Normal |

Use Monte Carlo simulation to calculate the probability of failure. Please give the 95% confidence interval for the MCS solution.

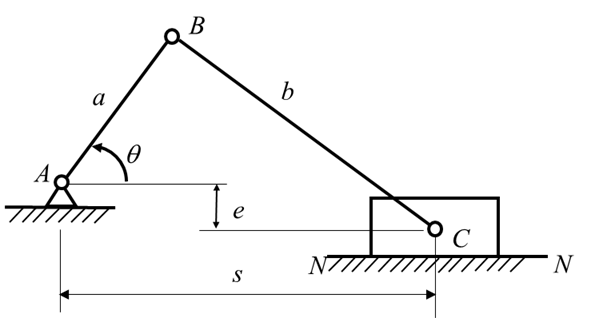

2.

The position of a slider-crank mechanism ![]() is

required to be 350 mm when

is

required to be 350 mm when ![]() . A failure occurs

if the actual position

. A failure occurs

if the actual position ![]() is outside the range

is outside the range ![]() mm. The tolerance of the three

independent dimension variables

mm. The tolerance of the three

independent dimension variables ![]() ,

, ![]() , and

, and ![]() is

is

![]() mm. Their distributions are given in

Table 2. Use Monte Carlo simulation (MCS) to calculate the probability of

failure. Please give the 95% confidence interval for the MCS solution.

mm. Their distributions are given in

Table 2. Use Monte Carlo simulation (MCS) to calculate the probability of

failure. Please give the 95% confidence interval for the MCS solution.

The distributions of the independent random variables are given below.

Table 2 Distributions

|

Variables |

Mean |

Std |

Distribution |

|

|

136.6 mm |

|

Normal |

|

|

216.8 mm |

|

Normal |

|

|

0 mm |

|

Normal |

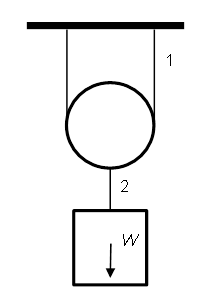

3.

(This is Question 5 in Homework 3.) The weight of

the crate follows a normal distribution ![]() . The allowable

tensions of the cables 1 and 2 are also normally distributed with

. The allowable

tensions of the cables 1 and 2 are also normally distributed with ![]() and

and ![]() , respectively.

The three random variables are independent. Determine the reliability of the

system. (Consider only the two cables. Neglect the weight of the pulley.) Compare

the simulation solution with the solution you have obtained before.

, respectively.

The three random variables are independent. Determine the reliability of the

system. (Consider only the two cables. Neglect the weight of the pulley.) Compare

the simulation solution with the solution you have obtained before.